Empowering Industries: How Electrical Components Drive Innovation and Efficiency

Companies that manufacture electrical components have a significant role in today’s industrial environment. The basic elements of every electronic system and gadget are electronic components. In an electronic system, electronic components are utilized to transmit electrons to carry out specific tasks.

Today electrical components manufacturing company is looking to promote innovation and efficiency in electronics production. The use of modern electronic components has increased industrial processes efficiency while also opening up fresh possibilities for productivity and innovation. Stay here to know about how electrical components drive innovation and efficiency:

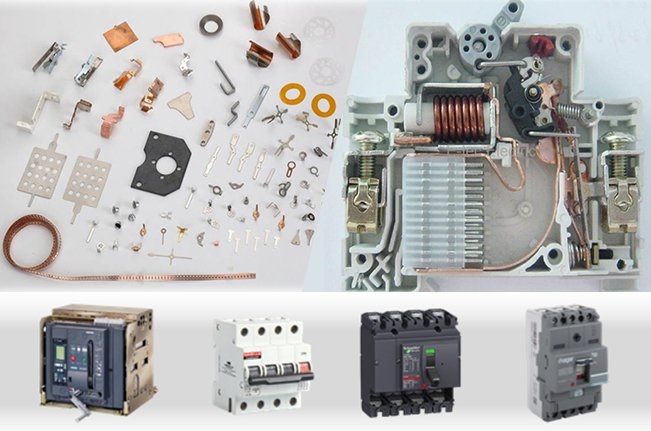

What are Electronic Components?

Electronic components are circuit parts that assist the electrical circuit function. Electronic components are the basic constituents of an electronic circuit, electronic system, or electronic device. They can control the flow of electrons inside an electrical system or circuit. To facilitate its easy transportation from one place to another. The price of electronic components is very low.

Electronic components consist of two or more terminals. A usable electronic circuit is established when a collection of electronic components is brought together on an electronic board, such as a printed circuit board. Each electronic component in a circuit serves a certain function. They are categorized into two types such as active and passive components.

Innovations and Efficiency in Electronic Components

Emerging Technologies

Emerging technologies are revolutionizing the world of electrical components manufacturing company. Flexible electrical devices use flexible substrates such as plastic or biological materials. As a result, the device is lightweight, flexible, and bendable.

Wearable electronics, folding defenses, and biomedical sensors are now possible due to technological breakthroughs. These use screen or inkjet printing to adhere electrical components to flexible shells.

This makes it possible to manufacture sensors and electronic circuits at an affordable cost. Flexible solar cells, disposable sensors, and smart packaging are new markets and applications made available by technology.

Miniaturization

The constant desire for smaller, more efficient components has resulted in one of the most significant advancements in electronic components. The advent of the integrated circuit and transistor led in a significant reduction in the size and complexity of electronic devices, igniting this trend.

As semiconductor manufacturing techniques improved, electronic components reduced, allowing for the creation of smaller, more power and energy-efficient gadgets. As a result, wearable technology, tablets, and cellphones with significant processing capability in small containers have become mainstream.

IoT

Many electrical stamping manufacturers use IoT technology in their production. IoT enables material tracking and maintenance planning, resulting in better logistics management and component longevity. For example, components in chip production are sensitive and prone to harm if not assembled on time.

Leveraging IoT with technologies such as RFID tagging improves assembly efficiency by ensuring parts are used on time, resulting in less damage and wasted materials. Smart technology may also detect and scan machinery and materials to assess whether components need to be replaced or repaired ahead of time, resulting in significant time and cost savings.

Efficiency and Performance

Electrical power components play an important role in increasing machine efficiency. Transformers, inverters, and converters all play important roles in ensuring that power is provided to the machine at the appropriate voltage and current.

This reduces energy waste and guarantees that equipment operates at top performance levels. High-efficiency motors and drives, for example, may drastically decrease electricity usage, affecting operational costs and industrial activities’ environmental imprint.

AI Applications in Electronics

AI has taken over electrical components manufacturing company. Electrical engineers are responsible for building complex AI-based technology to ensure a safer work environment in high-risk jobs. Electronic engineers can create AI-powered equipment that detects structural errors and alerts relevant authorities to fix such equipment to avoid disasters.

Control and Precision

Modern machinery frequently requires precise control over motion and operations. Speed, torque, and position can be precisely controlled using components such as variable frequency drives and servo motors.

This precision is critical in various applications, including robotics and CNC machines, conveyor systems, and HVAC controls. It directly impacts product quality, production speed, and system reliability.

Parting Words

Electrical components are more than just the basic building elements of modern technology. They are effective enablers of innovation and efficiency across a variety of sectors. These components create dramatic changes that improve efficiency and performance, ranging from manufacturing automation to smart solutions. Choosing high-quality electrical components and promoting innovation will continue to be crucial as industries deal with the challenges and opportunities presented by a technological world that is changing quickly.